Swaging

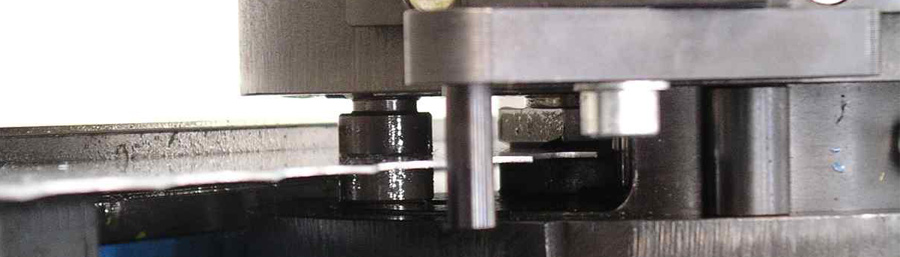

In September 2006 Ro-Ma extended the scope of its services by including swaging of saws toothing. This service is appropriate for wide band saws for sawmills. Swaging is performed using a hydraulically-controlled automated ISELI STA machine. The machine makes it possible to swage and equalise a saw during a single run. Equalising shapes side surfaces of a saw, ensuring equal size and identical shape on its both sides.

In September 2006 Ro-Ma extended the scope of its services by including swaging of saws toothing. This service is appropriate for wide band saws for sawmills. Swaging is performed using a hydraulically-controlled automated ISELI STA machine. The machine makes it possible to swage and equalise a saw during a single run. Equalising shapes side surfaces of a saw, ensuring equal size and identical shape on its both sides.

Swaging of toothing guarantees better results of sawing in both quantity and quality terms. Increased feed possible thanks to swaging translates into better efficiency of a saw. Swaging increases hardness of blade by 2 HRC on the average, thus improving its durability. Moreover, using saws with swaged toothing enhances sawing precision and ensures smoothness of surfaces of materials sawn. Such saws work in a more regular way, since teeth in the rift work using all the edge width. Thanks to better blade durability in effect of swaging, a service-free run time of a saw is longer.

Recommended swaging values are measured from the saw body to a side:

- in the case of wide band saws for sawmills:

| wide of saw | kind of wood | swaging values |

|---|---|---|

| 1,0 - 1,25 |

fresh, soft |

0,60 - 0,65 |

|

1,0 - 1,25 |

hard, frozen |

0,50 - 0,55 |

| 1,3 - 1,47 |

fresh, soft |

0,65 - 0,70 |

|

1,3 - 1,47 |

hard, frozen |

0,55 - 0,60 |

| 1,5 - 1,83 |

fresh, soft |

0,65 - 0,80 |

|

1,5 - 1,83 |

hard, frozen |

0,55 - 0,70 |

Available services:

- swaging of wide saws